Inquire

How Quality CNC Machining Solutions Ensure Consistent Product Quality

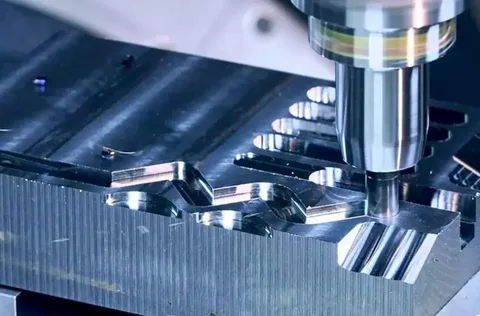

In today’s highly competitive manufacturing landscape, maintaining consistent product quality is not just a goal—it’s a necessity. Companies must meet stringent standards while optimizing efficiency to stay ahead of the competition. One of the most effective ways to achieve this is through advanced quality CNC machining solutions. CNC, or Computer Numerical Control, machining has revolutionized manufacturing by providing unparalleled precision, repeatability, and control over complex production processes.

By investing in quality CNC machining solutions, manufacturers can produce components with exact specifications, reducing the likelihood of errors and defects. These solutions allow businesses to maintain tight tolerances, ensure uniformity across production batches, and improve overall product reliability. In addition, they streamline operations by automating processes that were once labor-intensive, ensuring that every piece meets the required quality standards consistently.

Precision Engineering for Consistent Output

Precision is at the core of any successful manufacturing operation, and this is where quality CNC machining solutions shine. Unlike manual machining, CNC technology enables manufacturers to program highly detailed instructions into a machine, ensuring every component is produced with exceptional accuracy. This level of precision is critical for industries such as aerospace, automotive, and medical devices, where even minor deviations can compromise product performance and safety.

Moreover, the repeatability of CNC machines ensures that each part, whether it’s the first or the thousandth, matches the exact specifications. With quality CNC machining solutions, manufacturers can eliminate variability in the production process, leading to higher reliability and reduced waste. This capability not only supports consistent output but also enhances customer confidence, as buyers receive products that meet strict quality standards every time.

Reducing Errors Through Automation

Human error is an inevitable risk in manual manufacturing processes. Miscalculations, fatigue, or inconsistent techniques can lead to defects, increased costs, and production delays. Quality CNC machining solutions significantly reduce these risks by automating critical aspects of the manufacturing process. CNC machines follow precise digital instructions, minimizing the chance of mistakes caused by human intervention.

Automation also enables real-time monitoring of production parameters, allowing operators to detect deviations before they become significant issues. By integrating quality checks directly into the CNC process, manufacturers can maintain a higher level of accuracy and consistency. This approach not only ensures the production of high-quality components but also reduces the need for costly rework or scrap materials, ultimately boosting overall efficiency and profitability.

Enhancing Material Efficiency

Material wastage is a major concern in manufacturing, both in terms of cost and sustainability. Traditional machining methods often lead to excessive material loss due to trial-and-error adjustments and inconsistent cuts. With quality CNC machining solutions, manufacturers can optimize material usage through precise programming and computer-aided design integration. This allows for the creation of complex parts with minimal waste, ensuring every piece of raw material is used efficiently.

In addition to cost savings, improved material efficiency contributes to environmental sustainability. By reducing scrap and optimizing resource consumption, CNC machining aligns with modern manufacturing practices that prioritize eco-friendly operations. Businesses that invest in quality CNC machining solutions can achieve consistent product quality while simultaneously supporting sustainable production goals, reinforcing both economic and ethical advantages.

Scalability Without Compromising Quality

One of the most significant advantages of quality CNC machining solutions is the ability to scale production without sacrificing product quality. Traditional manufacturing methods often struggle with maintaining consistency when transitioning from small-scale to large-scale production. CNC machining, however, allows manufacturers to replicate parts with identical specifications regardless of production volume.

This scalability is essential for businesses looking to grow or respond to market demands quickly. By leveraging CNC technology, manufacturers can increase output while maintaining the same high-quality standards, ensuring that every product meets customer expectations. As a result, companies can confidently expand operations, secure larger contracts, and strengthen their reputation for delivering reliable, high-quality components consistently.

Advanced Monitoring and Quality Control

Maintaining consistent quality in manufacturing requires more than precision—it demands proactive monitoring and control. Quality CNC machining solutions often include integrated software systems that track performance metrics, machine conditions, and production outcomes in real time. This data-driven approach allows operators to identify potential issues before they affect product quality.

By combining CNC precision with advanced monitoring tools, manufacturers can implement rigorous quality control measures throughout the production cycle. From initial setup to final inspection, every stage benefits from data insights that ensure compliance with specifications. The result is a streamlined production process that consistently delivers products of the highest standard, reinforcing the value of investing in quality CNC machining solutions for long-term business success.

Conclusion

In a world where customer expectations and industry standards continue to rise, consistent product quality is a non-negotiable requirement for manufacturers. Quality CNC machining solutions offer the precision, repeatability, and control necessary to meet these demands, transforming manufacturing processes and ensuring that every component adheres to exact specifications.

From precision engineering and automation to material efficiency, scalability, and advanced quality monitoring, CNC machining provides a comprehensive approach to maintaining consistent product quality. Businesses that embrace these solutions not only improve efficiency and reduce errors but also strengthen their competitive edge in the market. Investing in quality CNC machining solutions is more than a technological upgrade—it’s a strategic move toward long-term reliability, sustainability, and customer satisfaction.

- Managerial Effectiveness!

- Future and Predictions

- Motivatinal / Inspiring

- Other

- Entrepreneurship

- Mentoring & Guidance

- Marketing

- Networking

- HR & Recruiting

- Literature

- Shopping

- Career Management & Advancement

SkillClick

SkillClick