Inquire

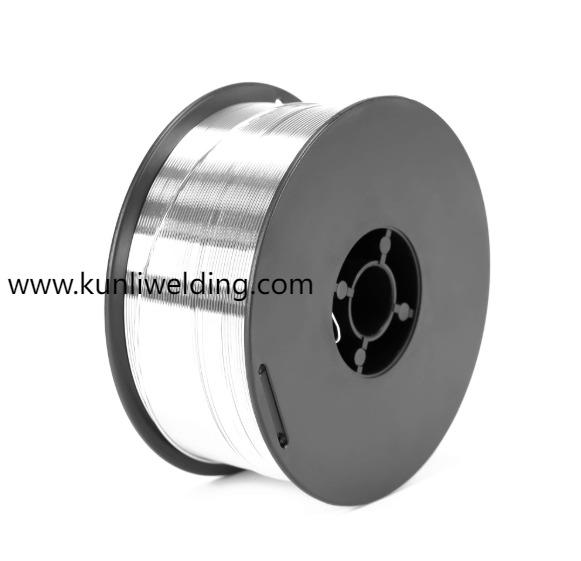

Optimize Infrastructure Builds with Kunliwelding Aluminum Wire

As global construction and energy projects expand rapidly, China Aluminum Alloy Wire Manufacturers have established themselves as key suppliers to markets worldwide. Their ability to balance quality, capacity, and cost efficiency has enabled fabricators and infrastructure developers to source conductors that meet demanding technical and commercial needs. From renewable energy farms in Europe to automotive plants in North America, these manufacturers leverage advanced metallurgy and streamlined logistics to deliver consistent performance on a global scale.

One driving factor behind this export dominance is production capacity. Major Chinese facilities integrate fully automated drawing lines and precision spooling systems to maintain tight diameter tolerances and smooth surface finishes. This level of automation reduces human error and ensures high throughput, allowing exporters to fulfill large orders quickly. When projects require tens of thousands of meters of wire, having a reliable partner who can scale up without sacrificing quality provides a significant advantage.

Cost competitiveness also plays a crucial role. Vertical integration across mining, smelting, and wire drawing stages helps control material expenses and currency fluctuations. By sourcing primary aluminum domestically and managing energy-efficient drawing processes, suppliers can offer attractive price points without resorting to shortcuts in quality control. For buyers operating under tight budget constraints, this cost-performance balance makes Chinese wire an appealing choice for both short-term procurement and long-term strategic partnerships.

Technical expertise further enhances the appeal of these exports. Research and development teams collaborate with global engineering firms to refine alloy chemistries tailored to specific applications, such as high-tensile conductors for aerospace or corrosion-resistant cables for offshore platforms. Sophisticated testing protocols—covering mechanical strength, elongation, and conductivity—are documented in detailed certificates, giving international customers the confidence that their wire meets or exceeds project specifications.

Supply chain resilience is another cornerstone of export success. Strategic warehouse networks and partnerships with leading freight carriers ensure that wire spools reach ports and inland distribution centers on time. Even as global trade routes face periodic disruptions, proactive inventory management and alternative routing options minimize the risk of project delays. Buyers investing in large-scale deployments benefit from transparent order tracking and responsive customer service that adjusts quickly to changing priorities.

Sustainability commitments are increasingly important for global stakeholders. Many China Aluminum Alloy Wire Manufacturers have adopted greener production practices, such as recycling scrap material and harnessing waste heat in extrusion furnaces. These measures reduce carbon emissions and align with international green building standards. For clients seeking materials that support corporate environmental goals, partnering with suppliers who prioritize resource efficiency helps meet broader sustainability mandates.

Innovation in surface treatments and conductor designs also sets Chinese exports apart. Specialized coatings improve wear resistance and compatibility with various insulation materials, while multi-strand braiding techniques deliver flexible cables for robotic and automation applications. Such innovations enable manufacturers to address evolving industry trends—like smart grid integration and electric vehicle infrastructure—by offering conductors that simplify installation and enhance long-term reliability.

Finally, cultural and regulatory alignment streamlines collaboration. Export teams fluent in multiple languages and familiar with diverse certification schemas—such as CE marking or UL listings—help international clients navigate compliance requirements smoothly. On-site audits and joint development workshops foster trust and reduce the lead time for qualifying new wire grades. This customer-centric approach ensures that projects stay on schedule, from initial prototype trials to full-scale production runs.

For engineers and procurement managers seeking a blend of capacity, cost-effectiveness, and technical sophistication in their conductor sourcing, exploring offerings from China Aluminum Alloy Wire Manufacturers can unlock new levels of performance and reliability. Discover how our extensive product lineup and dedicated support services can power your next project at www.kunliwelding.com .

- Managerial Effectiveness!

- Future and Predictions

- Motivatinal / Inspiring

- Altre informazioni

- Entrepreneurship

- Mentoring & Guidance

- Marketing

- Networking

- HR & Recruiting

- Literature

- Shopping

- Career Management & Advancement

SkillClick

SkillClick