The integration of Internet of Things (IoT) in industrial automation has redefined the traditional manufacturing ecosystem. From predictive maintenance to real-time analytics, IoT-enabled systems are enhancing productivity, minimizing downtime, and driving data-driven decision-making across industries.

Predictive Maintenance

IoT sensors collect vibration, temperature, and pressure data from machines. Advanced analytics algorithms predict failures before they occur, minimizing unplanned downtime and reducing maintenance costs.

Remote Monitoring & Control

Connected devices enable real-time monitoring of plant operations. Engineers can remotely access parameters such as motor speed, valve status, and energy consumption through cloud-based dashboards and SCADA systems.

Asset Tracking

RFID and GPS-integrated IoT devices provide end-to-end visibility of assets across the supply chain. This ensures efficient inventory management and minimizes equipment loss or misuse.

Energy Optimization

IoT energy meters analyze consumption patterns. Intelligent systems dynamically adjust power loads to enhance energy efficiency, lower carbon footprint, and reduce utility costs.

Industrial Safety & Compliance

IoT wearables monitor workers’ health indicators and exposure to hazardous environments. Integration with Industrial IoT (IIoT) platforms ensures compliance with OSHA and ISO safety standards.

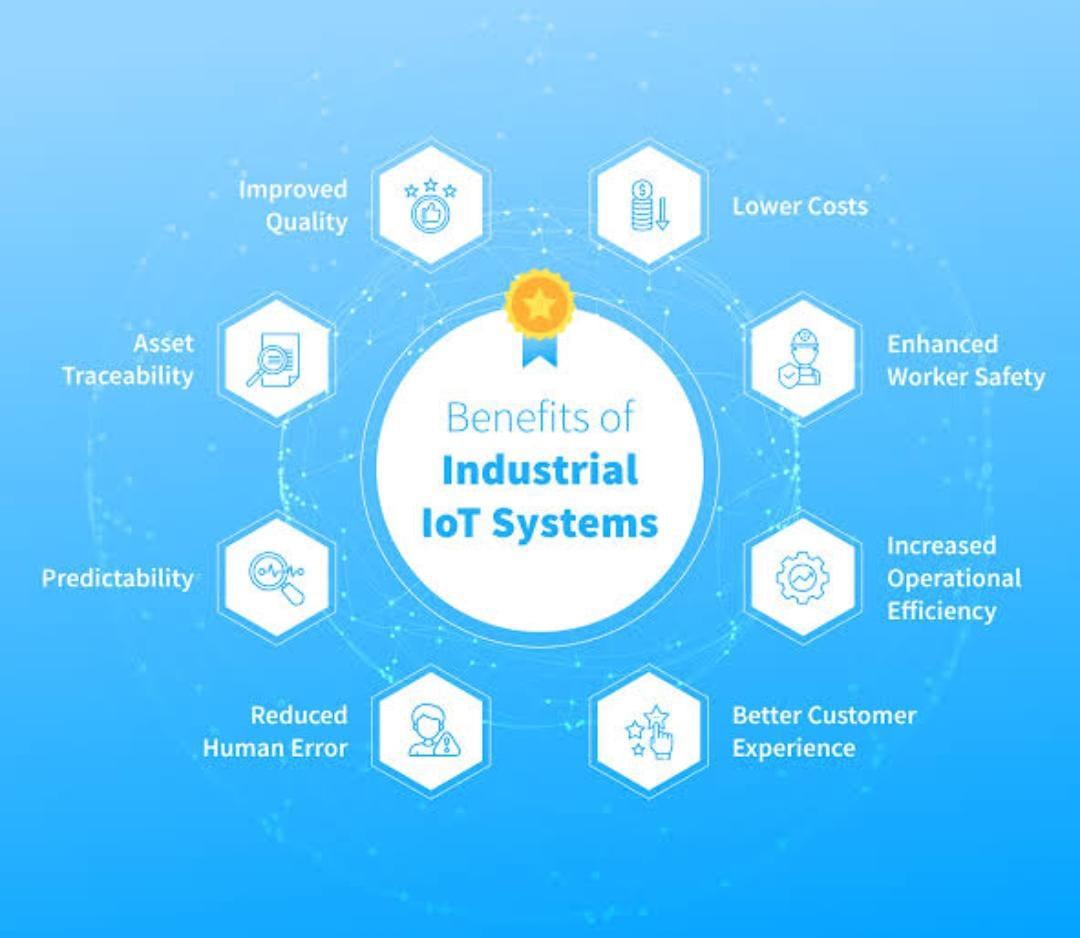

Benefits of IoT in Industrial Environments

-

Operational Efficiency: Automated control systems reduce manual intervention, speeding up processes and improving accuracy.

-

Data-Driven Insights: Big data analytics and edge computing enable informed decisions in real time.

-

Cost Reduction: Reduced breakdowns and optimized energy usage lead to significant cost savings.

-

Agility & Scalability: IoT systems support scalable architecture for flexible production lines and faster time-to-market.

-

Enhanced Quality Control: Sensors monitor product quality at each stage, ensuring defect detection before final assembly.

Conclusion

The convergence of IoT with industrial automation is the backbone of Industry 4.0. It is not just about connectivity, but about building smart factories where machines communicate, self-optimize, and learn from data. Embracing IoT is no longer optional—it's the foundation for sustainable, competitive, and future-ready manufacturing.

SkillClick

SkillClick