Inquire

Implementing Digital Twins in Startup Operations and Prototyping

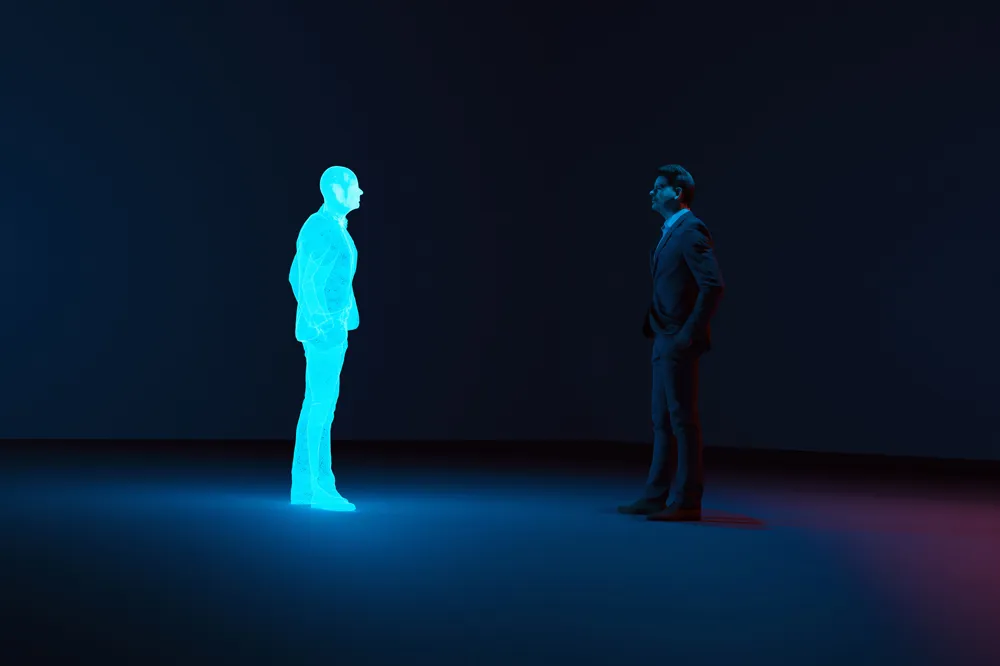

Digital twins are transforming the way products, systems, and operations are designed, tested, and managed. A digital twin is a dynamic, virtual representation of a physical object or process that uses real-time data and simulations to mirror the behavior and performance of its real-world counterpart. For startups aiming to innovate efficiently and at scale, digital twins offer a powerful way to accelerate development, reduce cost, and improve quality.

At its core, a digital twin integrates sensor data, machine learning, and analytics with 3D models and software simulations. This allows it to replicate the state, behavior, and functionality of physical assets with high accuracy. Whether it’s a mechanical component, a smart device, or a logistics system, a digital twin can simulate and predict how the real system will perform under various conditions, without the need for physical trial and error.

Startups can use digital twins in several impactful ways. During the prototyping phase, digital twins allow teams to test different design configurations and predict outcomes virtually. This reduces the need to build multiple hardware prototypes and speeds up the iteration cycle. For example, a company developing wearable health devices can use digital twins to model how the device interacts with the human body under different conditions .such as movement, sweat, or varying skin types.before producing physical samples.

Digital twins also support real-time monitoring and optimization. By continuously syncing with operational data, a digital twin can help identify inefficiencies, forecast potential failures, and recommend performance improvements. For instance, a digital twin of a delivery robot can monitor battery levels, route efficiency, and load capacity, providing insights that lead to better logistics planning and energy management.

Another major advantage is predictive maintenance. Digital twins can analyze usage patterns and environmental conditions to estimate when parts may wear out or malfunction. This enables timely maintenance and reduces unplanned downtime, which is critical for startups that rely on uninterrupted service or production. The result is increased reliability and lower operational costs.

Collaboration becomes easier with digital twins as well. Design and engineering teams can work together on a shared digital model, regardless of their physical location. This improves communication, reduces development delays, and ensures everyone is working with the latest version of the system. Advanced platforms also support integration with AR/VR tools, making it possible to interact with digital twins in immersive environments.

Despite the clear benefits, implementing digital twins does come with challenges. Accurate simulations require clean, high-quality data and a clear understanding of the system being modeled. Security and privacy also need to be considered, especially when working with sensitive data streams or connected devices.

However, with increasing access to cloud platforms, IoT sensors, and user-friendly development tools, digital twins are becoming more accessible to smaller teams and early-stage ventures. As startups continue to pursue smarter, faster, and more efficient solutions, digital twins will likely become a standard part of modern product development and operations.

Conclusion:

Digital twins offer a powerful, data-driven approach to innovation. By combining virtual modeling with real-time data, they help startups design better, operate smarter, and deliver faster ,all while reducing risk and cost.

- Managerial Effectiveness!

- Future and Predictions

- Motivatinal / Inspiring

- Autre

- Entrepreneurship

- Mentoring & Guidance

- Marketing

- Networking

- HR & Recruiting

- Literature

- Shopping

- Career Management & Advancement

SkillClick

SkillClick