Inquire

Is Aluminum Roller Design Evolving with Cbbmachine?

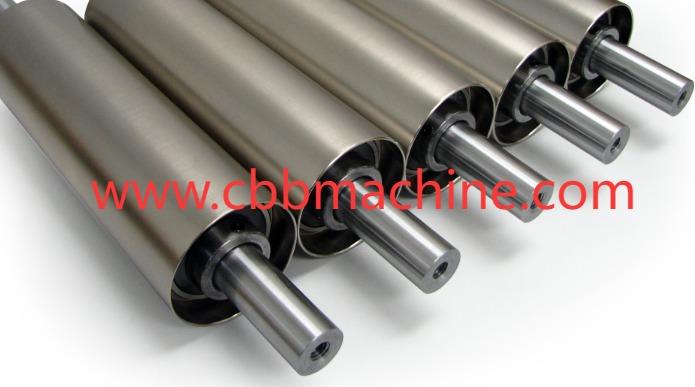

In today's manufacturing landscape, the Aluminum Roller plays a quiet yet essential role in maintaining smooth material movement, and Cbbmachine approaches this component with a focus on balance between structure and usability. Rather than relying on unnecessary complexity, the design philosophy centers on practical integration, supporting workflows where consistency and adaptability are valued.

Such rollers are commonly applied wherever materials need steady guidance, whether during conveying, winding, or surface processing. Their lightweight construction helps reduce rotational resistance, allowing systems to operate with less strain on connected equipment. This contributes to calmer operation and more predictable behavior across different stages of production.

Another important aspect is how these rollers support surface protection. When materials pass through multiple processes, even minor instability can lead to marks or misalignment. A well-finished roller surface helps maintain contact without excessive friction, supporting gentle handling while keeping materials on track. This is particularly useful in operations where visual quality and dimensional stability are closely monitored.

From an operational viewpoint, ease of installation and maintenance matters. Components that integrate smoothly into existing frameworks allow teams to make adjustments without interrupting the entire line. This flexibility supports gradual upgrades and process refinements, rather than forcing abrupt changes that can disrupt schedules and planning.

Long-term usability is also shaped by environmental adaptability. Rollers often work in varied conditions, including changes in temperature, speed, and load characteristics. Thoughtful material selection and structural design help ensure that performance remains steady across these variations, reducing the need for frequent intervention.

Beyond individual performance, rollers influence how a system feels to operate. Smooth rotation contributes to quieter lines and clearer feedback for operators, making it easier to detect irregularities early. This subtle transparency in operation supports preventive maintenance and encourages a more attentive production culture.

In a broader sense, choosing the right roller is about aligning equipment behavior with production intent. When motion feels controlled and reliable, planning becomes easier and confidence grows across teams. Small components, when carefully considered, often have an outsized impact on overall efficiency.

If these reflections resonate with your own production challenges, consider taking the next step. A visit to https://www.cbbmachine.com/news/industry-news/everything-you-need-to-know-about-aluminum-roller.html can open a door to detailed insights and practical ideas, waiting quietly for curious minds ready to explore further.

- Managerial Effectiveness!

- Future and Predictions

- Motivatinal / Inspiring

- Other

- Entrepreneurship

- Mentoring & Guidance

- Marketing

- Networking

- HR & Recruiting

- Literature

- Shopping

- Career Management & Advancement

SkillClick

SkillClick