Inquire

7 Key Advantages Of Creating Custom 3.5 Mylar Bags

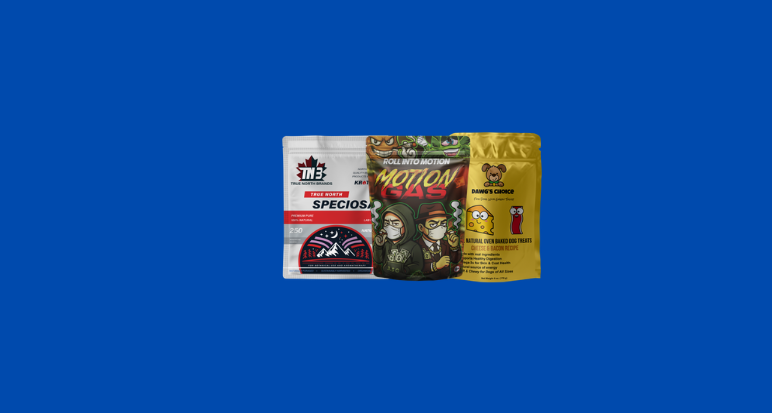

Custom 3.5 mylar bags offer a dependable, visually appealing, and defensive result for packaging products across diligence. Businesses aiming to save product quality, ensure safe transport, and maintain a professional reputation frequently rely on these pouches. from precise sealing to high- quality material selection, the manufacturing process combines effectiveness with customization. With a careful mix of accoutrements, printing, and finishing ways, these pouches meet both practical and aesthetic prospects for ultramodern product packaging. In addition, Custom 3.5 Mylar Bags allow for creative branding, icing each package communicates professionalism while securing contents. These pouches are particularly valued for humidity resistance, light blocking, and watertight sealing.

Understanding the Product Process of Custom 3.5 Mylar Bags

Mylar pouches involve multiple ways, each designed to ensure product safety and continuity. Raw accoutrements are named precisely to give inflexibility, strength, and hedge protection. Advanced manufacturing machines also convert flakes into precise bag sizes with accurate sealing and finishing.

Custom 3.5 mylar bags give exceptional protection for different products and are largely adaptable, supporting both retail and storehouse purposes. Power your brand with Custom Mylar Bags that are doable in any shape, style, color, print, or artwork. Submit a free quote to get an opportunity for complimentary design support, quick turnaround, and enjoy an exclusive discount of 15% OFF along no additional shipping cost.

SPECIFICATIONS

|

Style |

Doable in any style and shape |

|

Dimension (L + W + H) |

Any Size and Dimension is doable |

|

Quantities |

100 – 500,000+ |

|

Stock |

For Bags: Plastic (PET and Clear PET), Brown Kraft, Food gradable, and Aluminum |

|

Printing |

Printing (Digital or Plain), Flexographic Printing, Rotogravure Printing, Cold Foil Printing, PMS & CMYK Colors Scheme, Offset Lithography, and Spot Colors. |

|

Finishing |

Gloss and Matte Lamination, Gloss AQ, Gloss UV, Spot UV, Embossing or Debossing, Foiling (Gold, Silver, Copper, Red, Blue Foil Stamping) |

|

Additional Options |

For Bags: Resealable Closure, Zipper Lock, Heat Sealable, PVC Window Design, and Round/ Square Corner |

|

Turnaround |

For Bags: 12 – 14 business days after confirmation of design by our customers. |

|

Shipping |

Pack in Boxes then ship, through UPD, DHL, and FedEx. |

Accoutrements Used in 3.5 Mylar Bags

Opting for the right accoutrements is critical for performance and life. high- quality flicks give humidity resistance, UV protection, and perforation strength. Depending on the product conditions, manufacturers may use single- subcaste flicks or multi-layer laminates. Also, technical coatings or foils can increase hedge parcels while perfecting visual appeal.

Printing and Branding Ways

-

High-resolution printing ensures clarity for ensigns, product information, and ornamental patterns.

-

Techniques similar to lamination, matte or buff homestretches, and UV coating cover published shells and increase tactile sense.

-

Harmonious alignment and color delicacy support brand identity across all packaging units.

-

Pellet paragraph custom designs, clear window options, metallic antipode accentuations, and vibrant color printing raise product presentation.

Sealing and Finishing Styles

Sealing ensures product safety and newness. Heat-sealed edges, vacuum sealing, and resealable zippers offer multiple options for consumer convenience. Proper finishing, including edge trouncing and face smoothing, provides a professional look and prevents leakage. These measures inclusively increase the trustworthiness and appeal of custom 3.5 mylar bags.

Operations and Practical Uses

Mylar bags are protective, serving a variety of purposes across diligence.

-

Food packaging protects snacks, coffee, and dried goods from humidity and air.

-

Electronics storage prevents moisture damage while maintaining element integrity.

-

Retail display promotes imprinting through published ensigns and ornamental designs.

-

Subscription products maintain product newness for recreating deliveries.

Quality Assurance and Inspection

Regular examinations ensure that each bag meets manufacturing norms. machines test for perforation resistance, seal integrity, and invariant consistency. Visual checks confirm publishing quality and alignment. The final examination verifies that each unit meets the practicalal and aesthetic conditions necessary for retail or noncommercial use.

Benefits of Custom 3.5 Mylar Bags

Durable, seductive, and practical, these bags give multiple advantages for businesses. They guard products, reduce damage during transport, and support brand recognition through high- quality printing. Also, they're applicable and resealable, offering added value to consumers. Their inflexibility accommodates a variety of products, from food particulars to electronics, making them a leader in ultramodern packaging results.

"Your packaging should whisper your brand’s promise."

Environmental Considerations

Sustainability is an added focus in packaging. Numerous manufacturers offer recyclable films or factory- grounded druthers that maintain hedge performance. Reducing material waste, opting for eco-friendly inks, and encouraging responsible disposal each contribute to environmentally conscious packaging. Businesses can maintain protection and visual appeal without compromising environmental responsibility.

Tips for Bulk Production and Ordering

Effectiveness in bulk orders depends on accurate planning. Assessing volume conditions, specifying design details, and scheduling lead times ensure harmonious quality. businesses profit from lower per- unit costs, standardized appearance, and timely delivery

Conclusion

Understanding how custom 3.5 mylar bags are made allows businesses to elect packaging that protects products, increases branding, and meets consumer expectations. By fastening on accoutrements, printing, sealing, and quality control, companies can achieve harmonious and dependable results. Proper manufacturing processes ensure continuity, visual appeal, and usability across multiple operations. eventually, businesses that invest in well-made cmylar bags can ameliorate product safety, client satisfaction, and practical effectiveness while subtly incorporating Custom Packaging Solutions in the final delivery. Businesses can maintain protection and visual appeal without compromising environmental responsibility.

- Managerial Effectiveness!

- Future and Predictions

- Motivatinal / Inspiring

- Other

- Entrepreneurship

- Mentoring & Guidance

- Marketing

- Networking

- HR & Recruiting

- Literature

- Shopping

- Career Management & Advancement

SkillClick

SkillClick