Inquire

The Role of Rapid Prototyping Services in Cutting-Edge Manufacturing

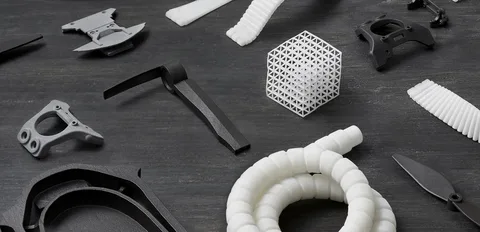

In today’s highly competitive industrial landscape, manufacturers are constantly seeking ways to innovate faster, reduce production costs, and bring high-quality products to market more efficiently. This shift toward agility and speed has led to the widespread adoption of rapid prototyping services, which play a transformative role in modern manufacturing. By enabling quick fabrication of design concepts, functional parts, and production-ready components, these services help companies compress development cycles that once took months into mere days. Rapid prototyping not only accelerates innovation but also empowers teams to refine their ideas in real time, bridging the gap between imagination and execution.

As industries evolve and consumer expectations rise, rapid prototyping services have emerged as indispensable tools for achieving precision and flexibility. Today’s manufacturers cannot rely solely on traditional methods that demand lengthy lead times and substantial financial investment. Instead, they need scalable and adaptable processes to keep pace with shifting market demands. This is where rapid prototyping services excel—offering speed, accuracy, and advanced manufacturing capabilities that drive the future of product development.

Enhancing Design Flexibility and Innovation

One of the most significant contributions of rapid prototyping services is the unparalleled level of design freedom they offer. Engineers and designers can now explore multiple design iterations quickly, unrestricted by the limitations of conventional manufacturing tools. Whether experimenting with complex geometries, intricate patterns, or unconventional forms, rapid prototyping allows the creation of physical models that would be nearly impossible—or extremely costly—through traditional methods. This freedom encourages risk-taking and creativity, enabling companies to push the boundaries of what is possible in product design.

Furthermore, rapid prototyping services foster an environment of continuous improvement. Instead of committing to a final design that may contain flaws or inefficiencies, manufacturers can evaluate prototypes at various stages, identify potential issues, and refine the product accordingly. This iterative design approach minimizes errors before production begins, reducing costly revisions later. As a result, businesses can achieve higher precision, smarter designs, and improved product functionality without compromising speed or efficiency.

Accelerating Product Development Cycles

The demand for faster product development is more pressing than ever. Companies that can bring their products to market quickly gain a substantial competitive advantage, especially in technology-driven sectors. Rapid prototyping services significantly shorten the development timeline by allowing teams to create physical models almost immediately after the design phase. Within hours, a digital concept can be transformed into a tangible prototype, enabling rapid assessment, testing, and modification. This accelerated workflow helps manufacturers meet tight deadlines while maintaining high quality.

Moreover, reducing the time between concept and market launch also boosts profitability. Faster iterations allow businesses to respond swiftly to consumer feedback, market trends, and unexpected challenges. By leveraging rapid prototyping services, manufacturers minimize delays associated with traditional manufacturing processes, such as mold creation or tooling adjustments. In industries where timing is everything—such as automotive, aerospace, and consumer electronics—this speed can mean the difference between leading the market and lagging behind competitors.

Improving Product Testing and Functional Validation

Beyond accelerating development, rapid prototyping services enhance product testing and validation, ensuring that the final product performs as intended. Manufacturers can create functional prototypes using materials that closely mimic the mechanical properties of the final product. These prototypes can undergo stress tests, usability tests, and performance evaluations, offering valuable insights into how the design behaves under real-world conditions. This early-stage testing helps eliminate design flaws before they escalate into more significant issues during mass production.

Additionally, rapid prototyping services facilitate communication across teams by providing a visual and tangible representation of a concept. Stakeholders—whether designers, engineers, investors, or customers—can interact with the prototype, assessing its ergonomics, aesthetics, and functionality firsthand. This hands-on evaluation leads to better decision-making and more efficient problem-solving. With fewer assumptions and greater clarity, manufacturers are able to achieve higher levels of precision and reliability in the final product.

Reducing Manufacturing Costs and Resource Waste

Cost efficiency is a major concern in modern manufacturing, and rapid prototyping services play a crucial role in reducing unnecessary expenses. Since prototypes can be produced quickly and often require minimal tooling, manufacturers avoid the high costs associated with traditional mold creation and machining. This affordability allows companies to test multiple design variations without straining the budget. As a result, rapid prototyping supports smarter financial decisions while enabling ambitious innovation.

Equally important is the reduction in material waste. Traditional manufacturing may involve subtractive processes that cut away large portions of material, leading to significant waste. In contrast, many rapid prototyping methods—particularly additive manufacturing—use only the material required to build the prototype layer by layer. This efficient use of resources not only lowers material costs but also contributes to sustainability goals. By adopting rapid prototyping services, companies align themselves with eco-friendly production practices and reduce their carbon footprint across the product development lifecycle.

Supporting Customization and On-Demand Production

As demand for personalized products grows, rapid prototyping services provide powerful solutions for creating customized parts quickly and cost-effectively. Industries such as healthcare, automotive, and consumer goods increasingly rely on these services to tailor products according to individual needs. Whether crafting custom medical implants, unique product variations, or limited-edition components, rapid prototyping enables manufacturers to deliver personalized solutions without the lengthy delays typically associated with custom production.

Additionally, rapid prototyping services support the growing trend of on-demand manufacturing. Companies no longer need to maintain large inventories or commit to mass production runs when they can create components precisely when needed. This reduces storage costs and the risk of unsold inventory, enabling more agile production systems. By integrating rapid prototyping into their workflows, manufacturers gain a highly responsive and scalable approach that aligns with modern supply chain strategies.

Conclusion

Rapid prototyping services have become essential tools in the evolution of cutting-edge manufacturing, offering unprecedented advantages in speed, innovation, cost savings, and precision. By empowering businesses to quickly transform ideas into functional prototypes, these services streamline development cycles, enhance design quality, and support flexible, on-demand production. As industries continue to embrace digital transformation and advanced manufacturing technologies, rapid prototyping will remain a driving force behind creative engineering, efficient workflows, and superior product outcomes.

Companies that invest in rapid prototyping services are better positioned to stay competitive, respond to market changes, and deliver high-quality products that meet the expectations of modern consumers. In a world where innovation is key to survival, rapid prototyping stands as the foundation of agile, intelligent, and future-ready manufacturing.

- Managerial Effectiveness!

- Future and Predictions

- Motivatinal / Inspiring

- Other

- Entrepreneurship

- Mentoring & Guidance

- Marketing

- Networking

- HR & Recruiting

- Literature

- Shopping

- Career Management & Advancement

SkillClick

SkillClick